For over 25 years, Harvan Manufacturing Ltd. has delivered a wide range of quality precision components using CNC machining, welding, laser and waterjet cutting, and other value-added services. For quality assurance, we comply with many industry certifications and standards, including ISO 9001:2015; CWB Div 3, CSA W47.1; and the Controlled Goods Program. We operate out of a 49,000-square-foot facility that houses all the equipment and materials we need for every solution.

Learn more about our precision CNC machining services in Ontario, including our advantages and cutting-edge equipment.

What Is CNC Machining?

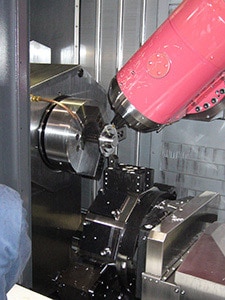

Computer numerical control (CNC) machining manufactures standard and custom industrial components for various applications. This process relies on different types of programmed equipment, including lathes, mills, and grinders. These automated systems produce complex components for manufacturers with a level of precision not possible through manual or conventional machining. The superior versatility and productivity of CNC machining allow for the development of fully customized components and parts. Potential end products include brackets, screws, shafts, hinges, bolts, and much more.

Advantages of Harvan’s CNC Machining Services in Ontario

CNC machining offers a variety of advantages to any production operation. Here are the key benefits of working with Harvan for your CNC machining needs.

High-Volume Repeatability

To meet high-volume production demands, CNC machining can help. CNC machines can be programmed to replicate and mass-produce products of consistently high quality.

Reduced Labor Costs

CNC machining maximizes productivity while minimizing labor costs. Because it is an automated process, a single operator can oversee multiple workstations, optimizing ROI.

More Production Options

CNC machining allows you to produce complex components not possible through manual machining. CNC software updates continually improve the technology and available production options to enhance functionality.

Save Time and Money

You can use CNC software to realize ideas virtually and create prototypes through CNC machining. This saves valuable time and money on labor and materials.

What to Expect When Working With Harvan

Harvan Manufacturing Ltd. uses a proven CNC machining process to develop top-quality, high-precision components of all types. The following are the specific steps we take when you work with us:

- Receiving a quote — The first step of our process entails reviewing your technical data, drawings, and blueprints. Based on these items, our team will determine which process will work best for manufacturing. From there, we’ll provide an estimated quote for both cost and timeline.

- The ordering process — Upon receiving purchase orders from our customers, we input them into our enterprise resource planning (ERP) system. At this point, we’ll ensure pricing and revisions align with the quote and conduct a complete review of your contract.

- Creating the job — The next phase involves planning, where we determine if there’s any remaining stock from prior projects that we can use for your order or if we need to create a new job.

- Review by an engineer — Following job creation, our engineers review the job before approval. The engineer ensures that quoted materials meet all order and drawing comments.

- Releasing the job — Once the engineer approves the job, we purchase the necessary raw materials and begin the project. Once we receive the materials from our suppliers, we thoroughly inspect them to make sure they are the right size and grade. We also review the certificates that verify the materials meet the standards for their intended project. Every step of this process is traceable through heat numbers, lot numbers, and other specifications.

- Manufacturing — After completing all paperwork, we’ll initiate the manufacturing process using the designated materials and processes, which may include cutting, welding, turning, milling, deburring, assembly, and more.

- Final inspection/shipping — Every finished product undergoes a quality check before shipping to the customer.

The Average Lead Time

The average lead time will depend on certain factors affecting the project. In most cases, if we must purchase new materials, the lead time is around 12 to 14 weeks. If the customer supplies materials and only requires machining services, the lead time shortens to around 4 to 8 weeks, depending on difficulty and quantity requirements.

Our CNC Machining Equipment

Our fleet of CNC machining equipment includes the following.

CNC Lathe Machines

9 Axis:

- Mori Seiki NT 4300DCG/1500SZ Mill Turn

- Mori Seiki MT2000SZ LatheMill – Barfeeder

5 Axis:

- Mori Seiki NL2500Y-700SY sub spindle

- Mori Seiki NL3000Y-1250

- Mori Seiki NL3000Y-700

- Mori Seiki NL2500Y-700

4 Axis:

- Mori Seiki NL1500-700

- Mori Seiki ZL-250/600

- Mori Seiki ZL-25B/500

- Mori Seiki ZL-25B/1000

2 Axis:

- Mori Seiki SL-15

- Mori Seiki SL-4

CNC Milling Machines

- Toyoda FA-800, CAT50, 60 Tools

- Mori Seiki NH5000 DCG/50, CAT50, 54 Tools

- Toyoda FA-550 II, CAT50 40 Tools, U-axis

- Haas VF-1 & VF-4, VF-5 VMC, CAT40, 20 Tools

- Haas UMC-750 5 Axis mill

- Enshu VMC-430, CAT40, 25 Tools

View our full equipment list here.

Why Use Our CNC Machining Services in Ontario

If you require CNC machining in Ontario for your next manufacturing project, we’re here to help.

Our conveniently located Ontario facility sits along the major 401 Hwy corridor, which ensures quicker and more efficient product delivery to customers in Ontario and in U.S. border states. This proximity facilitates easy shipping throughout North America.

To learn more about our manufacturing capabilities, contact us today, or request a quote to get started on a project. You can also reach out to us using the contact information below.

Harvan Manufacturing Ltd.

612 Jack Ross Ave.

Woodstock ON N4V1B6

Phone: 519-537-8311

Email: harvan@harvan.com