Harvan Manufacturing Ltd. has over 30 years of experience in creating high-quality, customized components for diverse industries. Waterjet cutting and laser cutting, two of our core competencies, are economical processes that are effective in manufacturing parts with precision cuts. If you’re looking for Ontario waterjet cutting and laser cutting services, read on to learn more about these methods and partnering with Harvan.

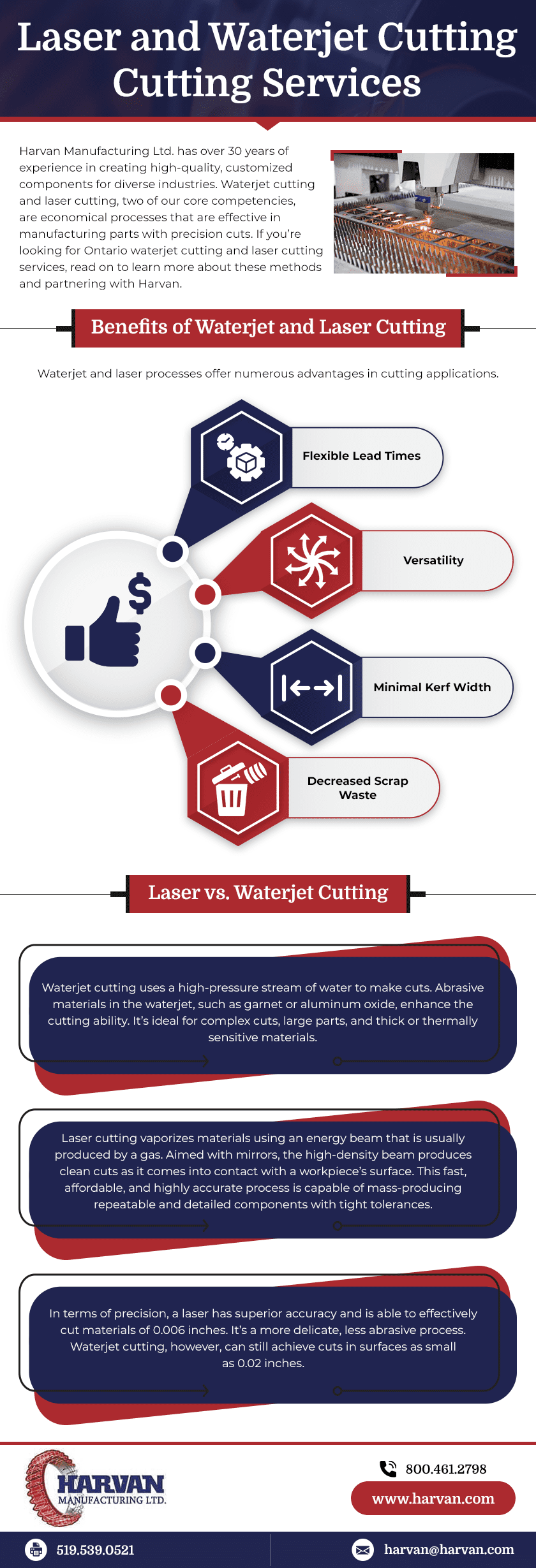

Benefits of Waterjet and Laser Cutting

Waterjet and laser processes offer numerous advantages in cutting applications.

Precision Accuracy Compatible With Automation

Waterjet and laser cutting create components with excellent precision. They can accurately generate cuts with high repeatability, consistently producing parts with the same dimensions and specifications each time for ideal uniformity within a production run. This makes these techniques well-suited for automation.

Flexible Lead Times

By incorporating automation into these cutting methods, we’re able to offer improved output and flexible lead times without sacrificing part quality.

Versatility

These techniques are quite versatile, in both material usage and process capabilities. Laser cutting is suitable for mild and stainless steels. In our waterjet cutting operations, we typically work with stainless steel, aluminum, and thicker materials. The processes themselves are also flexible, enabling us to customize parts for wide-ranging applications to meet your unique specifications.

Minimal Kerf Width

Waterjet cutting is capable of a kerf width, or the width of material a process removes from a workpiece per cut, of approximately 0.01 inches. Laser cutting offers a small kerf width, as well. As a result, these techniques achieve intricate detail and complex shapes with thin cuts.

Decreased Scrap Waste

These cutting procedures don’t generate much waste. In addition, what scrap they do produce is generally recyclable or otherwise reusable, making these processes advantageous for their sustainability.

What Is the Difference Between Waterjet and Laser Cutting?

Waterjet cutting uses a high-pressure stream of water to make cuts. Abrasive materials in the waterjet, such as garnet or aluminum oxide, enhance the cutting ability. It’s ideal for complex cuts, large parts, and thick or thermally sensitive materials.

Laser cutting vaporizes materials using an energy beam that is usually produced by a gas. Aimed with mirrors, the high-density beam produces clean cuts as it comes into contact with a workpiece’s surface. This fast, affordable, and highly accurate process is capable of mass-producing repeatable and detailed components with tight tolerances.

Precision: Laser vs. Waterjet Cutting

In terms of precision, a laser has superior accuracy and is able to effectively cut materials of 0.006 inches. It’s a more delicate, less abrasive process. Waterjet cutting, however, can still achieve cuts in surfaces as small as 0.02 inches.

What to Expect When Working With Harvan

When working with Harvan for laser or waterjet cutting, our customers can expect these steps:

- Receiving a quote. We review any drawings and technical data you have to ensure our team understands the proper materials, processes, and timing considerations for the job, generating a quote through our ERP system based on those factors.

- Ordering. Customer purchase orders go into our ERP system, helping us confirm that all pricing matches up with the quotation. We also complete a contract review during this stage.

- Creating a job. If we can’t ship from stock, we put a job package together for manufacturing what we need to fill a purchase order. This includes drawings, material needs, inspection reports, and more for effectively planning the job timeline and quantity.

- Engineering review. The engineering department checks that all revisions and drawings match the job and your purchase order, creates inspection reports, and generally confirms the actual manufacturing requirements.

- Purchasing raw materials and releasing the job. We work with our suppliers to obtain the needed raw materials for the order, only releasing a job once we’ve received and inspected the materials.

- Manufacturing. Waterjet and laser cutting are two of our gateway operations. We utilize a CO2 laser type on Mazak Space Gear Mark II Laser equipment, and Flow MACH 4-4020B equipment for waterjet cutting. This stage also includes finishing, assembly, and quality checks.

- Inspecting and shipping. Our quality assurance team will carry out a final inspection on all manufactured parts, following ISO 9001 requirements. Once approved, products transfer to the shipping department for packaging.

Why Use Our Waterjet and Laser Cutting Services in Ontario?

Family-owned and -operated, Harvan Manufacturing Ltd. prides itself on having manufactured quality components for over 30 years. Our Woodstock, Ontario, facility is right along the major 401 Highway corridor to ensure fast, efficient delivery to customers in Ontario and bordering U.S. states, with shipping across North America. Call us at 519-537-8311, email us, or use our online form to request a quote today.