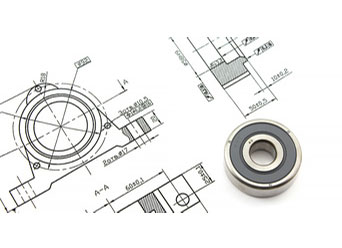

Engineering CAD/CAM (2D or 3D)

Our Engineering team uses SolidWorks to design, analyze and modify parts and assemblies in 3D space. It also enables us to create and work with drawings alongside our customers. We use MasterCam to create programs for our CNC machines, enabling us to perform complex machining operations that would otherwise be impossible.

Prototyping

Harvan is frequently involved in prototyping projects with our customers and can offer valuable insight on how to increase quality and make a product easier to manufacture, thus reducing costs.

Subcontractors

Harvan Manufacturing Ltd. has an extensive network of subcontractors to handle all metal finishing, heat treating, coatings, Stellite hard face welding or third-party inspections which may be required to complete your parts.

Finishing

We have in-house lapping, burnishing, cylindrical and centerless grinding, balancing, pre-twisting, polishing and magnetic particle inspection (MPI) capabilities to streamline the processing of your parts.

Assembly

Our Assembly Team completes mechanical and electrical assemblies in our assembly and staging area which is flexible in size from 5000 to 15,000 square feet. We can handle subassemblies or complete assemblies up to 1000 lb. We can handle anything from pressing bearings or adding fasteners to machined components, to hydraulic and lift assisted large assemblies.