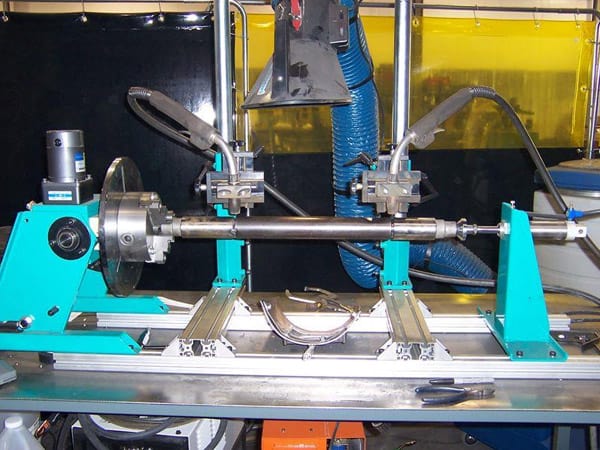

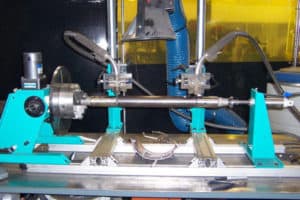

At Harvan Manufacturing Ltd., our team strives to surpass your expectations for welding and metal fabrication services. We utilize a complete line of state-of-the-art equipment in our certified job shop to produce components in accordance with international industry codes and quality standards. Harvan Manufacturing also performs in-depth inspections ranging from macro-etch to visual inspections in-house to ensure that products meet stringent quality assurance standards starting with the prototyping phase all the way through shipping. Read on to learn more about our capabilities in welding and metal fabrication in Ontario.

Our Welding and Fabrication Capabilities

Harvan offers comprehensive welding and fabrication services to fulfill the needs of a myriad of applications.

High-Quality Welding for a Variety of Metals

Offering both contract and prototype welding services in Ontario, Harvan is qualified to handle everything from high-volume orders to one-off pieces for specialty applications. Our capabilities include:

- Gas metal arc welding (GMAW). GMAW is a gas-shielded metal arc welding technique in which an electric arc forms between a consumable electrode and the base metal to generate heat and fuse materials.

- Metal inert gas (MIG) welding. This arc welding method uses a welding gun and a consumable electrode of continuously fed bare wire filler or a flux core to join conductive metals.

- Tungsten inert gas (TIG) welding. Versatile TIG welding utilizes a non-consumable electrode, filler rod, and a torch to produce the heat and arc required for forming a welded joint.

At Harvan, we work with a variety of materials, including carbon and stainless steel, aluminum, titanium, cobalt, copper and nickel alloys, and exotic metals.

Types of Fabrication Available at Our Facility

Our metal fabrication services turn raw metal materials into pre-made components for future assembly. We utilize numerous fabrication techniques, each requiring experience and practiced expertise to effectively achieve the best results. These processes generally necessitate specialized machining processes and tooling, as well.

The certified, experienced Harvan team has the capability to perform a number of in-house fabrication processes at our Ontario facility based on client needs, including:

- Bending

- Forming

- Assembly

- Laser cutting

- Waterjet cutting

Our Welding and Fabrication Process

We tailor our manufacturing approach to meet your unique technical requirements, timeline, and budget by following these general steps:

- Obtaining the quote. After receiving part blueprints and technical data, we determine the best processes and materials for production and produce a quote using our ERP system.

- Processing the order. We enter your purchase order information into our ERP system and confirm that the pricing and revisions align with the quoted amount. We also perform a contract review to check quality clauses and related paperwork.

- Creating the job. For new or custom jobs, our ERP system creates a job package that includes everything from drawings and inspection reports to process flow and material requirements. Our job planners review all information to determine part quantities and estimated lead times.

- Completing an engineering review. Our engineers review the job information to optimize the manufacturing plan and ensure that the drawings and revisions align with your purchase order. We also create inspection reports of critical dimensions for our machinists.

- Releasing the job to production. Next, we provide an updated quote that accounts for any changes in raw material costs. After thoroughly inspecting materials from suppliers and reviewing the associated paperwork, we release the job for manufacturing.

- Manufacturing. This process typically begins with a gateway operation (waterjet cutting, laser cutting, etc.) followed by the required fabrication or welding process. Lastly, we perform any necessary value-added finishing or assembly services, as well as quality inspections.

- Final inspection and shipping. Harvan’s quality assurance team performs a final inspection before packaging and shipping the product, with inspection reports available upon request.

The Average Lead Time

The time required to complete a welding project can range from two to seven months or more depending on your requirements and the overall complexity of the project.

Benefits of Using Harvan Manufacturing for Your Ontario Welding and Fabrication Needs

Our welding and fabrication capabilities allow us to consistently outperform our competitors in Ontario. Working with Harvan enables you to take advantage of our ISO 9001:2015- and CSA W47.1-certified job shop, which adheres to such industry standards as AWS and ANSI codes. Our commitment to high-quality workmanship shows in our prototyping and manufacturing services, with tight tolerances of ±0.010 inches on parts. Also, we can generate detailed quality reports as a result of our inspections for peace of mind.

Why Use Our Custom Welding and Fabrication Services in Ontario?

Backed by over 30 years of experience and a state-of-the-art welding and fabrication equipment line, Harvan Manufacturing meets the needs of diverse industries for clients across North America. Our convenient location in Woodstock along the Highway 401 corridor facilitates fast shipments throughout the rest of Ontario and the bordering American states.

To learn more about our Ontario welding services and fabrication capabilities, you can reach us by phone at 519-537-8311, email, or our contact and request for quote online forms.