Harvan Manufacturing is an industry-leading metal parts manufacturer headquartered in Woodstock, Ontario. For over 25 years, we have been a trusted name in CNC machining, cutting, welding and fabrication. Our quality work has allowed us to form long-term partnerships with numerous Canadian defense companies, including:

- Rolls-Royce Canada Limited (naval division for navy ships)

- Textron

- General Dynamics Land Systems Canada

- Naval Marine

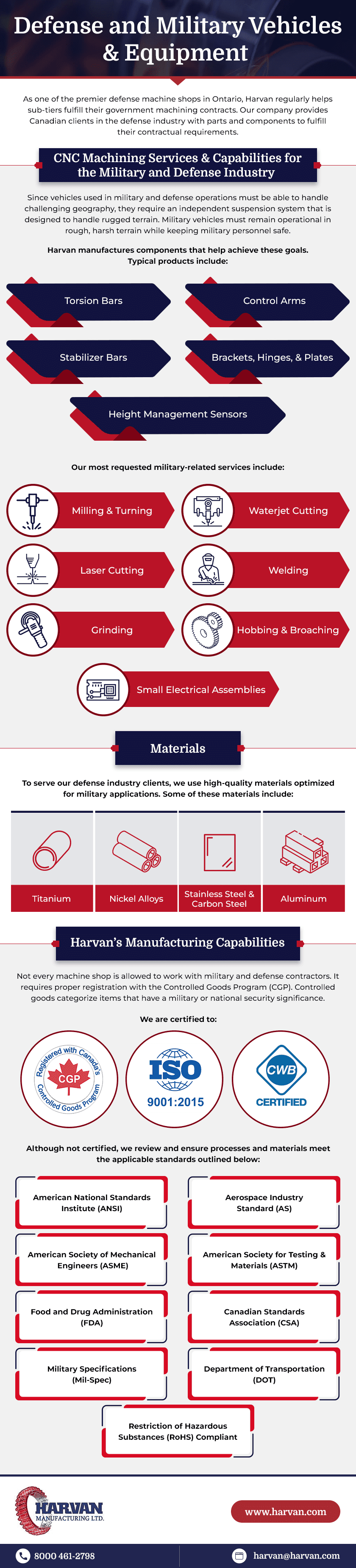

As one of the premier defense machine shops in Ontario, Harvan regularly helps sub-tiers fulfill their government machining contracts. Our company provides Canadian clients in the defense industry with parts and components to fulfill their contractual requirements.

CNC Machining Services & Capabilities for the Military & Defense Industry

Since vehicles used in military and defense operations must be able to handle challenging geography, they require an independent suspension system that is designed to handle rugged terrain. Military vehicles must remain operational in rough, harsh terrain while keeping military personnel safe.

Harvan manufactures components that help achieve these goals. Typical products include:

- Torsion bars

- Control arms

- Height management sensors

- Stabilizer bars

- Brackets, hinges, and plates

CNC machining plays a critical role in manufacturing these parts. Our CNC capabilities include 2-axis, 4-axis, & 9-axis machines. This diversity of operations allows us to create high volumes of complex pieces with high precision and tight tolerances. Our skilled welders and metalworkers can meet our defense clients’ strict specifications for performance, fit, and quality to ensure user safety.

Our most requested military-related services include:

- Milling & Turning

- Waterjet Cutting

- Laser Cutting

- Welding

- Grinding

- Hobbing & Broaching

- Small Electrical Assemblies

Materials We Work With in Defense Projects

To serve our defense industry clients, we use high-quality materials optimized for military applications. Some of these materials include:

- Titanium: In recent years, titanium has grown in popularity in the aerospace and defense industry. The material’s corrosion resistance, low thermal expansion, reliability, and excellent strength-to-weight ratio have made it a top choice for extreme environments. Titanium is also highly machinable, producing components such as airframes, armor, and other structural parts.

- Nickel alloys: Most defense industry applications demand strength and quality, so they often use nickel alloys. Key attributes of nickel alloys include memory hysteresis, low thermal expansion, electrical resistance, and more.

- Stainless steel & carbon steel: These two types of steel are widely used in the defense industry, and for good reason. Stainless steel provides excellent corrosion resistance and high durability. Carbon steel is preferred when components demand less ductility. Examples include knives, bayonets, and other hand-held instruments used by military personnel.

- Aluminum: Aluminum has been used in military equipment since 1892. From ammunition to armored vehicles, aluminum remains an important material for military equipment. The alloy provides several key benefits, such as a high strength-to-weight ratio, corrosion resistance, electrical and thermal conductivity, reflectivity, and impermeability.

Harvan’s Manufacturing Certifications

Not every machine shop is allowed to work with military and defense contractors. It requires proper registration with the Controlled Goods Program (CGP). Controlled goods categorize items that have a military or national security significance.

The CGP registration regulates controlled goods in Canada with the intent of strengthening the country’s defense trade controls. While Harvan doesn’t work directly with the military, many of our clients do. As part of the CGP registration program, we have clear security plans, maintain visitor logs, and keep a detailed inventory of all areas where controlled goods may be present.

Our registration and certifications don’t end with CGP. Additional credentials include:

- American National Standards Institute (ANSI)

- Aerospace Industry Standard (AS)

- American Society of Mechanical Engineers (ASME)

- American Society for Testing and Materials (ASTM)

- Controlled Goods Program (CGP) Certified

- Canadian Standards Association (CSA)

- Canadian Welding Bureau (CWB) Division 3 Certification

- Department of Transportation (DOT)

- Food and Drug Administration (FDA)

- International Organization for Standardization (ISO) 9001:2015

- Military Specifications (Mil-Spec)

- Restriction of Hazardous Substances (RoHS) Compliant

Work With Harvan Manufacturing Ltd.

No matter the client or industry, we pride ourselves on delivering dependable precision components. If you have any questions about our capabilities, contact us. If you already have a project in mind, feel free to request a free quote. You can also reach us via the contact info below:

Harvan Manufacturing Ltd.

612 Jack Ross Ave.

Woodstock, ON N4V1B6

Phone: 519-537-8311

Email: harvan@harvan.com