The Basics of CAM Engineering

Leave a CommentAt Harvan Manufacturing Ltd., we’ve manufactured high-quality industrial parts and products for over 30 years. This extensive experience, combined with a highly skilled team, top-of-the-line equipment, and CAD/CAM engineering enables us to provide new or replacement components to customers in a wide range of industries, including, but not limited to, agriculture and forestry, military and defense, valves and controls, and off-road vehicles and heavy trucks.

We rely on a variety of advanced tools and equipment to ensure each phase of the manufacturing process proceeds smoothly, from CAD/CAM software during the design and engineering phase to precision machining equipment during the manufacturing phase. Altogether, these technologies allow us to ensure we provide customers with the best possible parts and products.

What Is CAD to CAM Engineering?

Computer-aided manufacturing (CAM) refers to manufacturing operations that utilize computer software and computer-controlled machines to achieve better product quality and/or process efficiency. It is generally used in conjunction with computer-aided design (CAD) software, which enables designers and engineers to create digital models of the desired part and product that dictate how it should look and work. This information is then loaded to the CAM software, which creates instructions for the equipment (e.g., CNC machining units) that direct them on how to create the component.

Applications of CAM

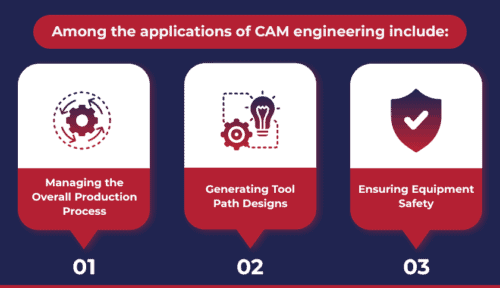

CAM has a number of uses in manufacturing facilities, such as:

- Managing the overall production process. CAM software can be used to automate production operations, allowing for more operational efficiency.

- Generating tool path designs. CAM technology can be used to dictate the movement of tools and equipment to ensure the workpiece is worked into the proper shape and size.

- Ensuring equipment safety. Computer-controlled equipment reduces the risk of manufacturing mistakes as well as employee injury due to falling materials, chemical exposure, extreme heat, and other adverse conditions.

Benefits of Using CAD/CAM Technology in Manufacturing

By utilizing CAD/CAM technology in their facilities, manufacturers benefit in many ways, including:

- Broader manufacturability flexibility. CAD/CAM software enables manufacturers to take on jobs (e.g., the manufacture of highly complex components) that would be otherwise impossible to fulfill by manual methods.

- Better client accessibility. CAM/CAM software allows manufacturers to readily receive and process client-provided CAD models, resulting in faster project cycle times.

- Greater project oversight and control. CAD/CAM software makes it easier for manufacturers to maintain oversight and control over various aspects of the job, including design or production updates, material inventory, and machining operations.

- Easier programming. CAD/CAM software takes the guesswork out of setting up manufacturing units, making it simple for machine operators to input and update the necessary equipment settings. Additionally, many CAD vendors have developed CAM machining modules that readily integrate with CAD software, making it easy for new designers and machine operators to learn and use them.

- Higher productivity. CAD/CAM software improves the efficiency of machining operations by allowing for faster speeds without sacrificing accuracy or precision.

- Lower waste generation. CAD/CAM software reduces the risk of mistakes during the manufacturing process, which, in turn, decreases the amount of rejected pieces.

CAD/CAM Engineering Capabilities at Harvan

At Harvan, our manufacturing experts primarily utilize the following software programs to facilitate the fulfillment of customer projects:

- Powered by SOLIDWORKS’ patented iMachining technology, this software offers fast tool paths and efficient programming. It has single-window integration and full associativity with the SOLIDWORKS design model, allowing for automatic updates to tool paths in response to design model changes.

- This software is suitable for basic to complex CNC programming needs. It supports production needs from design to manufacturing, resulting in streamlined operations from project setup to completion.

Our team uses these CAD/CAM software programs to design, analyze, and modify 2D and 3D designs and develop machine programs from CNC machining projects. We also use it for various value-added operations as needed.

Harvan: Ensuring Quality With CAD/CAM Technology

CAD/CAM technology offers many benefits to manufacturers. At Harvan, we use it to ensure we provide our industrial customers with parts and products that fully meet their specifications and standards. If you need quality components you can trust for your critical applications, we’ve got you covered. To learn more about our manufacturing capabilities, contact us today. To discuss your manufacturing needs with one of our experts, request a quote.