Harvan Manufacturing offers custom precision machining for a variety of industries, including agriculture, farming, and forestry. We offer extensive experience in the machining, welding, and fabrication of Power Take-Off (PTO) parts for high-torque, low-speed equipment. Over more than 30 years, we’ve expanded our facilities to incorporate 49,000-square-feet of manufacturing space for the machining and fabrication of high-precision farm and forestry machinery parts.

Even the simplest PTO components demand tight tolerances and the use of high-quality metals. At Harvan Manufacturing, our highly skilled machinists, engineers, and technicians can guarantee tolerances within ±0.001 inches for straightness, concentricity, outer diameter (OD), and inner diameter (ID). Using advanced computer numerical control (CNC) machines, Harvan delivers the highest levels of precision with short lead times.

What is PTO?

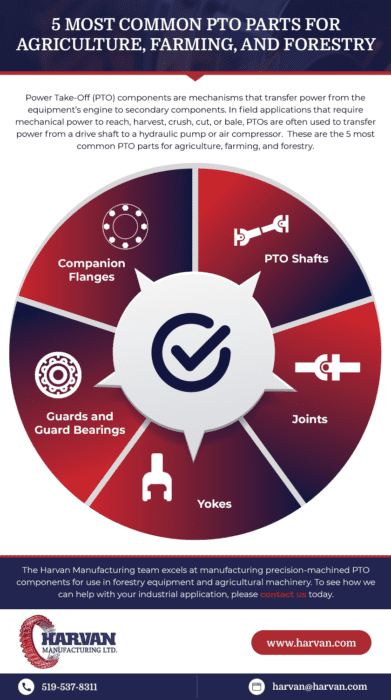

PTO components are mechanisms that transfer power from the equipment’s engine to secondary components. In field applications that require mechanical power to reach, harvest, crush, cut, or bale, PTOs are often used to transfer power from a drive shaft to a hydraulic pump or air compressor. Without power take-off technology, agriculture and forestry equipment would not possess the torque, horsepower, speed, rotation, or grip to perform the heavy-duty operations in the field.

The 5 Components Often Manufactured for PTO

The following most frequently manufactured PTO components should be selected according to equipment specs and the power needs of the driven equipment.

PTO Shafts

Most farm and forestry equipment requires a means of transferring rotational power and torque from the engine to the PTO-driven machine or implement. A PTO shaft rotates in proportion to the speed of the engine, providing the rotational energy for powering agricultural implements like woodchippers, excavators, and rotary tillers. Important specs include the horsepower rating at specified RPM, number of splines and series size, and whether the shaft will be installed with a live PTO or independent PTO.

Joints

PTOs use U-joints and constant velocity (CV) joints to keep the PTO shaft transmitting power from the transmission to the drive wheels, especially on uneven and demanding terrain. CV joints are a necessary part of front-wheel drive vehicles, allowing the drive shaft to transmit power at constant rotational speed through different angles. Universal joints are common on rear-drive vehicles and are mounted on both ends of the drive shaft. When connected to yokes, U-joints allow movement along or parallel to the shaft, which is necessary when traveling over bumpy roads.

Common machining specifications for PTO joints include the outside diameter of the bearing cap, the location of the snap ring, and end-of-cap to end-of-cap measurements.

Yokes

Implement yokes assist in maneuvering heavy equipment by connecting the machine’s driveline to agricultural implements such as a power tiller, cultivator, or plow. The flange yoke is a U-shaped attachment with a flat-face that mates with a companion flange on driveshafts, resulting in a mechanical connection able to handle the torque required to rotate the driveline shaft.

Quick-disconnect shaft yokes use a push-pin mechanism for easy connection of the cross and bearing kit to the driveline shaft, while a tube yoke requires a second cross and bearing kit to connect the implement.

Companion Flanges

Companion flanges mate with a flange yoke and feature a precision-machined face, drive bore, and through holes or threaded holes for connection to the appropriate companion flange yoke. Both the yoke and companion flanges must be capable of handling high torque loads and are machined for exceptional balance.

Guards and Guard Bearings

PTOs typically rotate at speeds of 540 RPM or 1,000 RPM. Guards and guard bearings prevent accidental pull-in or caught-in injuries. A master shield to guard the tractor PTO stub and connection end in combination with a driveline shield offers maximum protection. PTO implement guards protect against unintentional contact with driveline components and protect the point where the driveline connects to the implement.

PTO Components From Harvan Manufacturing

The Harvan Manufacturing team excels at manufacturing precision-machined PTO components for use in forestry equipment and agricultural machinery. To see how we can help with your industrial application, please contact us today.